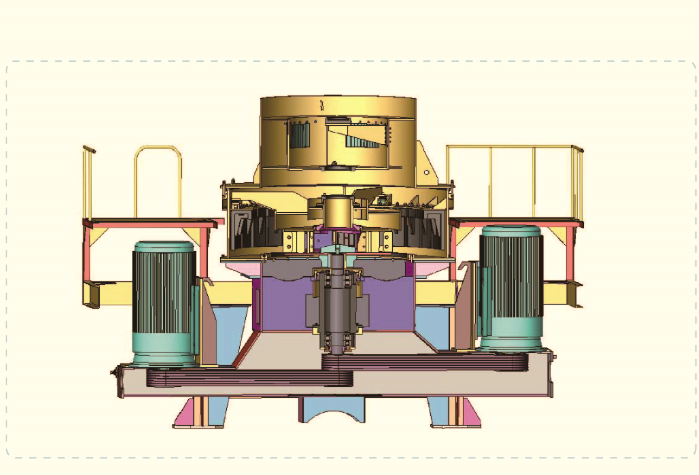

PL series deep-chamber vertical impact crusher

is one of our latest products which is designed by totally updating the

original PL series vertical impact crusher based on 15 years’ manufacture

experience and the feedbacks from more than one thousand customers with the

newest design concept and the most advanced processing workmanship.

It follows the original mutual stone beating operation principle of the

original vertical impact crusher and owns advantage of high crushing efficiency

and good product shapes. Also, the brand new deep-chamber rotor technology it

applied further increases the output and lower the component and energy consumption

of the unit product. The utilization of the damageable parts is obviously

increased through brand new optimized design of the layout, providing more efficient

protection for the machine body; The key components is made of the most

advanced hard alloy, which leads the actual application trend of the technological

achievements; The human-based design makes the operation and maintenance more

convenient and easier.

In the basis of the characteristics mentioned above, the B series

deep-chamber vertical impact crusher reduces the manufacture cost to the lowest

while gaining the high-quality aggregate, which is your best choice in

production!

1.

The application of the brand new deep-chamber rotor technology is the key

to success of the B series deep-chamber vertical impact crusher.

2.

The launching mouth height of the deep-chamber rotor is about

50% bigger than that of the normal rotor, which means the space between the

distribution cone and the impeller guard ring and that between the upper and

lower runner plates are bigger.

3.

Expansion of the internal space makes the rotor be

capable of including more feeding materials, whose handling capacity is as high

as 30% above.

4.

Expansion of the internal space makes it smoother when the materials are

casted from the rotor and greatly reduces the abrasion of the upper and lower

runner plates when the materials pass, increasing the lifespan of the rotor

parts.

5.

The machine can offer the largest utilization with little maintenance down

time.