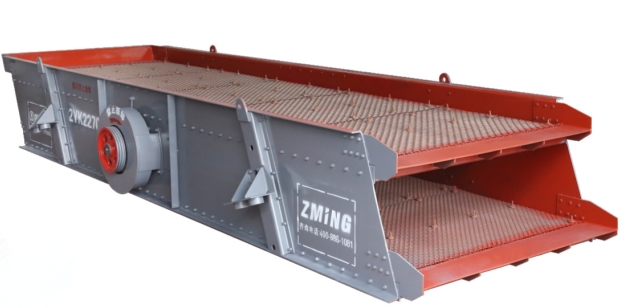

YK series self-centering variable amplitude vibrating screen is the new patented product which combines the Germany advance technology with the actual domestic situation of the industry. It is mainly applicable for stonework, mine, construction material, etc. This machine works stably when starts or stops. It can automatically adjust the excited force and the amplitude based on the material flow amount during production, greatly reducing the blocked issue that easily occurs in the normal homemade screens. It is a high-efficient screening machine of classifying the broken materials like stones, ore, etc.

The operation principle of this vibrating

screen is that the electromotor drive the vibrator with eccentric device

through V-belt and makes the screening box vibrate, whose moving track is

round. The vibrating screen consists of the screening box, vibrator, spring

vibrating device and supporting base, etc. The screening box is made of high

quality alloy steel plate which is connected by high-strength bolts, composing

the frame structure. The vibrator adopts stepless variable amplitude eccentric mechanism

and the spring vibrating device adopts high quality coil spring.

1. Stable starting and stopping. It adopts the advanced vibrating technology of

self-centering excitation from Germany, which overcomes the resonance

phenomenon and keep the stable starting and stopping of the machine, lowering

the noise.

2. Durable screening box with long lifespan. It adopts high-quality alloy

steel plate and is joint with high-strength bolts, making the long durability

and life span.

3. High effective power and low power dissipation, energy-saving and environment-friendly.

4. Stepless amplitude variation.

5. Non-blocking screen net. Continuous change of the excitation overcomes the

frictional resistance between the materials and the screen net, preventing the

blocking issue effectively, saving the operation time while lowering the labor

cost.

6. High screening efficiency. The vibrating effect of the stepless amplitude

variation greatly improve the screening efficiency. Especially for the

screening of the fine material, the screening efficiency is 20% higher than

that of the normal screen.

7. Top-standard sealed effect. Double labyrinth-type seal has outstanding

sealed effect, obviously extending the oiling lubrication period and lowering

the labor cost and lubricating oil cost.